In modern industrial environments, cybersecurity risks are increasing faster than ever. Critical infrastructures such as power plants, oil and gas facilities, water treatment systems, and transportation networks rely heavily on OT and ICS systems. These networks were originally designed for stability—not security—and are now frequent targets of cyberattacks.

One of the most reliable technologies developed to prevent unauthorized access and protect sensitive operational data is the Data Diode, a hardware-based one-way data transfer device.

What Is a Data Diode?

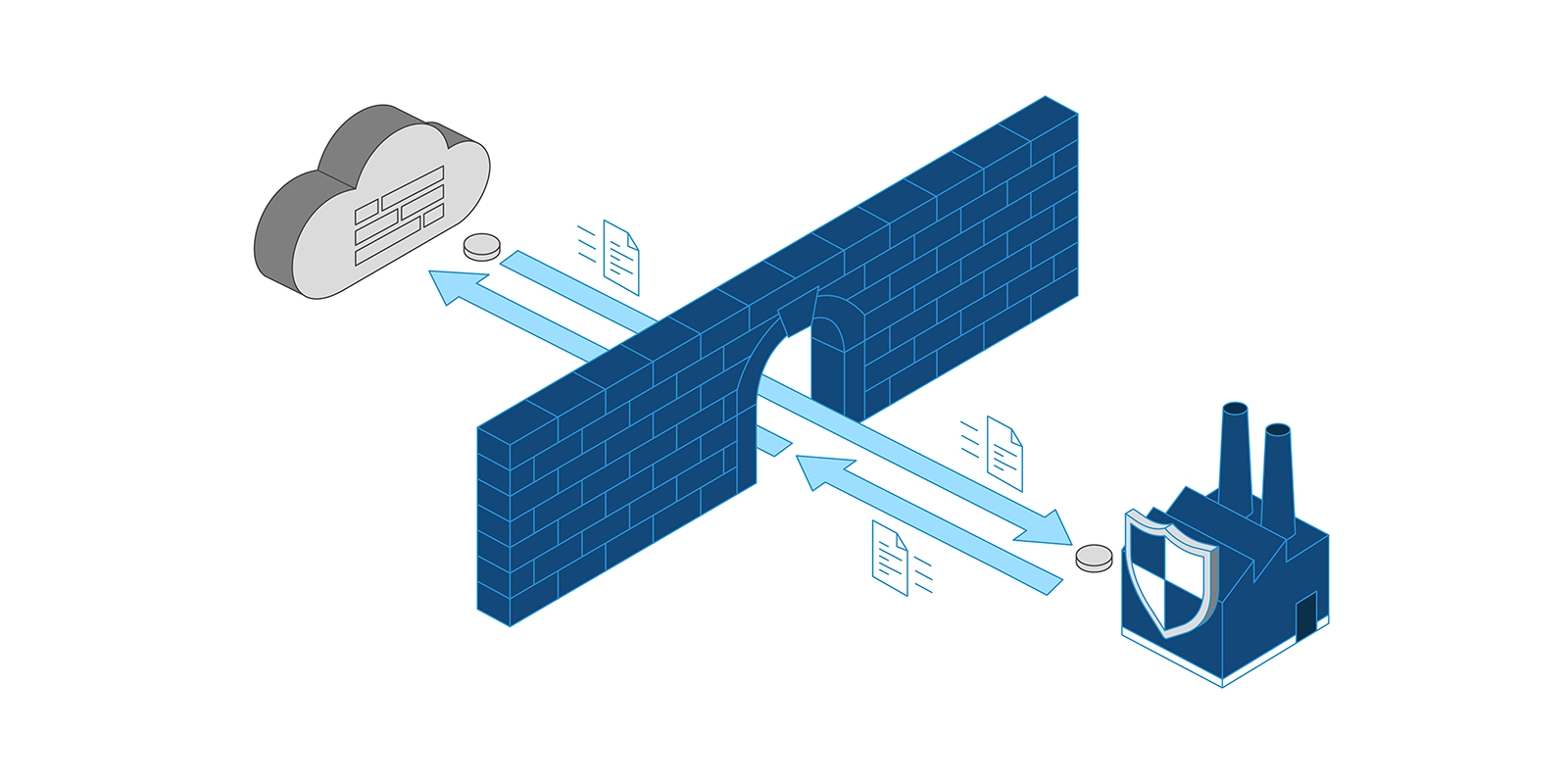

A data diode is a physical, hardware-enforced one-way communication device that allows data to move in only one direction—from a secure network to a less secure network—without any possibility of reverse communication.

Unlike firewalls, which depend on software rules and are vulnerable to misconfiguration and zero-day exploits, data diodes use physical separation to guarantee that no data can ever return to the protected network.

This makes them one of the most trusted technologies for high-security industries.

How Does One-Way Data Transfer Work?

A data diode uses hardware logic that allows only outbound data flow.

Here’s what happens internally:

Data is transmitted through a TX-only channel

The RX path does not physically exist → making reverse communication impossible

Attackers cannot send packets, commands, malware, or exploits back into the secure network

The secure network remains isolated, even while sending telemetry or monitoring data to external systems

This design provides absolute protection against:

Malware injection

Network scanning

Remote command execution

Ransomware propagation

Zero-day vulnerabilities

Why Industrial Networks Need One-Way Data Transfer

OT/ICS environments often support equipment that must run continuously and cannot tolerate downtime. A cyberattack could result in:

Production shutdown

Safety hazards

Environmental damage

Financial loss

Manipulation of sensors and controllers

A data diode prevents these threats by ensuring:

Protected control network → cannot be accessed from outside

Monitoring data → can safely leave the secure network

This balance of visibility and protection is why many industries consider data diodes essential.

Comparison: Firewall vs. Data Diode

Key Benefits of Using Data Diodes

1. Maximum Security with Zero Attack Surface

No operating system, no software vulnerabilities—pure hardware.

2. Guaranteed No Return Path

Even if the external network is fully compromised, it cannot send anything back.

3. Compliance with Industrial Security Standards

Many frameworks now recommend or require unidirectional gateways (e.g., ISA/IEC 62443).

4. Stable 24/7 Operation

Designed for mission-critical environments.

5. Protects Legacy Systems

Older OT equipment cannot be patched—but can be isolated with a data diode.

Common Use Cases of Data Diodes

SCADA data transfer to enterprise networks

Secure communication between control room and monitoring center

Logging and telemetry collection

Remote monitoring of industrial processes

Protecting critical infrastructure from cyberattacks

Isolating OT networks from IT networks

Safe integration with cloud platforms

Where Does the G200 Industrial Data Diode Fit In?

The G200 Industrial Data Diode is a hardware-based one-way transfer device developed specifically for OT/ICS and SCADA networks.

It provides:

True one-way data transfer

OS-less architecture for maximum security

Support for multiple industrial protocols

Reliable 24/7 operation

Complete physical isolation between secure and insecure networks

Learn more about the G200 here

Conclusion

Data diodes are among the most secure and effective technologies for protecting industrial networks. With rising cyber threats targeting critical infrastructures, organizations need a reliable method to guarantee network isolation without sacrificing visibility.

One-way data transfer technologies like the G200 ensure operational continuity while eliminating the possibility of inbound cyberattacks.

If your organization handles critical operations, now is the time to consider implementing a hardware-based data diode solution